Home

Secondments

Recruitments

Publications

Talks

Conferences

| Name of researcher |

Michael EIGENSATZ |

| Recruited at project partner |

Evolute |

| Starting date |

2010-07-01 |

| Duration of recruitment |

2 years |

| Short description |

The

central topic of my recruitment was to research, implement, and test

single curved panelisations of freeform surfaces with specialized panel

types motivated by practical requirements. The general computational

framework for D-Strip models should be extended to support the

specification of practical constraints like the angles and gaps between

panels and specialized to integrate practically relevant panel types

like cylinders and cones or ruled panels. The theory and results

developed in the 2 years of my recruitment were published in the most

important scientific as well as industrial conferences and journals in

the field of architectural geometry. The implementation was applied and

validated on real world architectural projects and helped in the

realization of some of the most prestigious architectural structures of

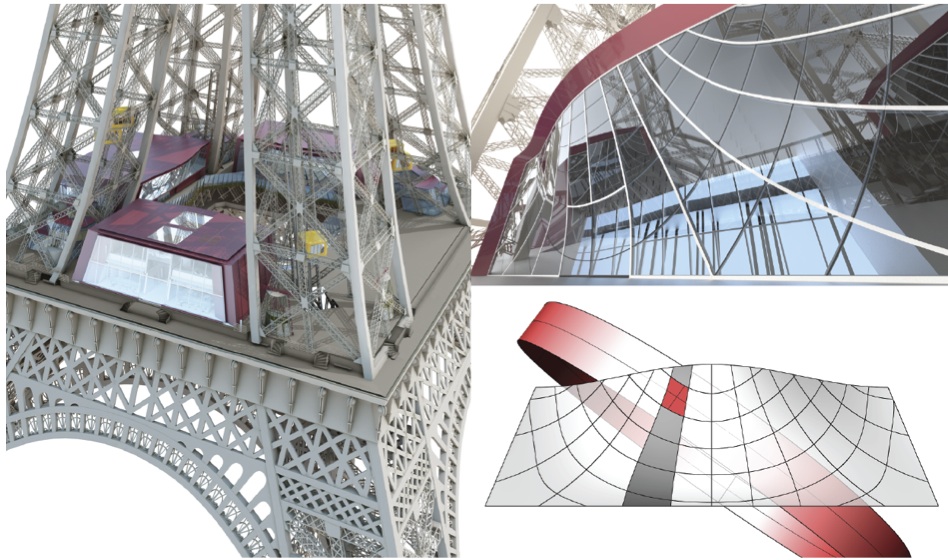

the recent years. The Eiffel Tower Pavilions, Paris – The results of the ARC project were applied for the panelisation of the glass façades of the new pavilions that are currently under construction on the first floor of the Eiffel Tower. The double curved façade was panelized using only affordable single curved (cylindrical) panels and, due to the results developed during my recruitment, was still meeting the high quality tolerances and constraints. |

| Name of researcher |

Giovani Gomez ESTRADA |

| Recruited at project partner |

RFR |

| Starting date |

2011-09-02 |

| Duration of recruitment |

16 months |

| Short description |

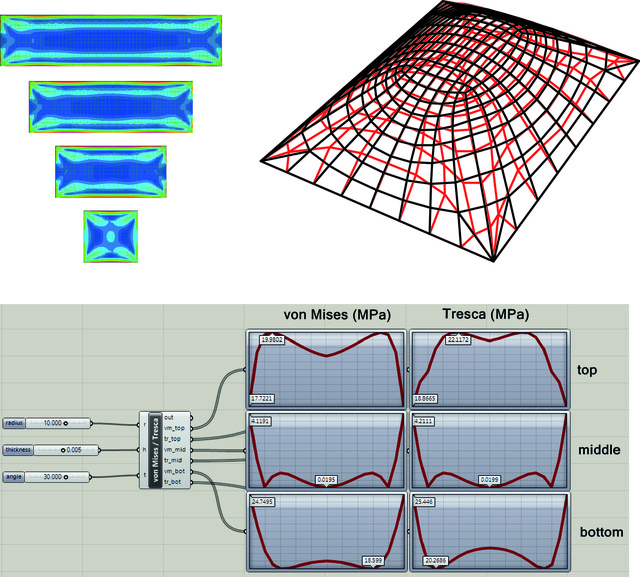

There is an

on-going trend in architecture to employ glass surfaces of curved

forms. Developable glass panels formed from cold bending techniques

provide better visual characteristics, in a less time- and energy

consuming manner than traditional hot bent panels. Since every

cold-bent panel is mechanically fixed to its final frame, they are

continuously subjected to bending stresses. It is thus important to

carefully analyse the internal forces created during the fabrication

process and lifetime. I worked on two projects: (1) direct calculation of von Mises and Tresca stresses for cold-bent glass panels; and (2) combined form-finding and planarisation of glass domes.  |